BIM SERVICES

- Home

- Services

- BIM Services

- Digital Fabrication

Digital Fabrication

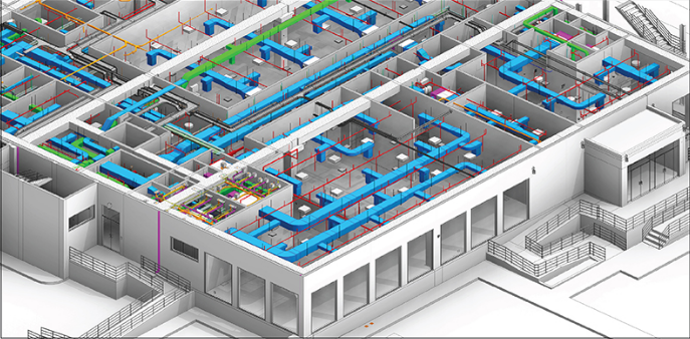

For Meplex, BIM isn’t the finish line—it’s the launchpad. We push beyond 3D coordination into DfMA (Design for Manufacture & Assembly), computational design, and automated production. Using parametric modeling and rule-based assemblies, we convert coordinated BIM into fabrication-ready deliverables that drive CNC, robotics, and modular/pre-fab workflows. The result mirrors mature manufacturing sectors: repeatable quality, tighter tolerances, faster throughput, and dramatically less waste.

Our pipeline is end-to-end and data-tight: concept modeling → parametric/kit-of-parts design (Rhino.Inside, Grasshopper, Dynamo) → LOD 400/450 detailing with tolerances and clearances → spools, shop drawings, and BOMs → nesting and CAM/CNC outputs → kitting, barcoding, and QA traceability → 4D assembly sequencing and field installation guidance. We support structural steel, MEP spools, façade panels, bathroom pods, riser modules, and other off-site assemblies, integrating with your vendors’ machines and your CDE for closed-loop control.

What this means for your project: shorter schedules through off-site production and parallelized workstreams; lower cost from standardized parts and lean inventory; higher safety by shifting labor offsite; and consistent, audit-ready quality. With Meplex, digital fabrication isn’t a buzzword—it’s a practical, governed workflow that turns federated BIM into real, manufactured components that install first-time-right and feed your digital twin for operations.